NEO and KOROYD an Engineering Partnership for improved paragliding harness protector

Posted by Martin Havel on

NEO X KOROYD : AN ENGINEERING PARTNERSHIP

A 9-YEAR PARTNERSHIP DEVELOPING PRODUCTS

Neo and Koroyd have been working together to develop safer paragliding products since 2014.

The first tests lasted two and a half years until the correct combination of Koroyd and foam was found to meet the standards and obtain the certification for paragliding. During these tests, we realized that the Koroyd technology by itself was not enough and needed to be used with a special casing. We then joined forces with Koroyd to develop a custom-shaped foam for this need. The NEO-KOROYD technology, tested and registered, was born from this collaboration.

Our common goal has always been to develop protection technology for paragliding harness that, throughout the years, has allowed reducing the thickness, weight, and volume of protections while maintaining their shock-absorbing capacity.

ABOUT KOROYD

Koroyd has been committing to innovation for a safer future for over 10 years. Their unrelenting search for smarter, safer, and more durable protection solutions is recognized by patented and awarded innovations.

Koroyd and their team operate worldwide. Their headquarters are located at the Monaco Principality and their team is present in the United Kingdom, North America, and China. Koroyd works throughout 5 major commercial units: Sports, Motorsports, Industrial Safety, Family and Defense, and distribute their technology to clients all over the world: from the United States to South Korea.

Thanks to their expertise in various domains, they provide their partners with an in-depth expertise regarding the user's demands, R&D installations, and setup protocols to offer remarkable protection solutions.

HOW KOROYD WORKS

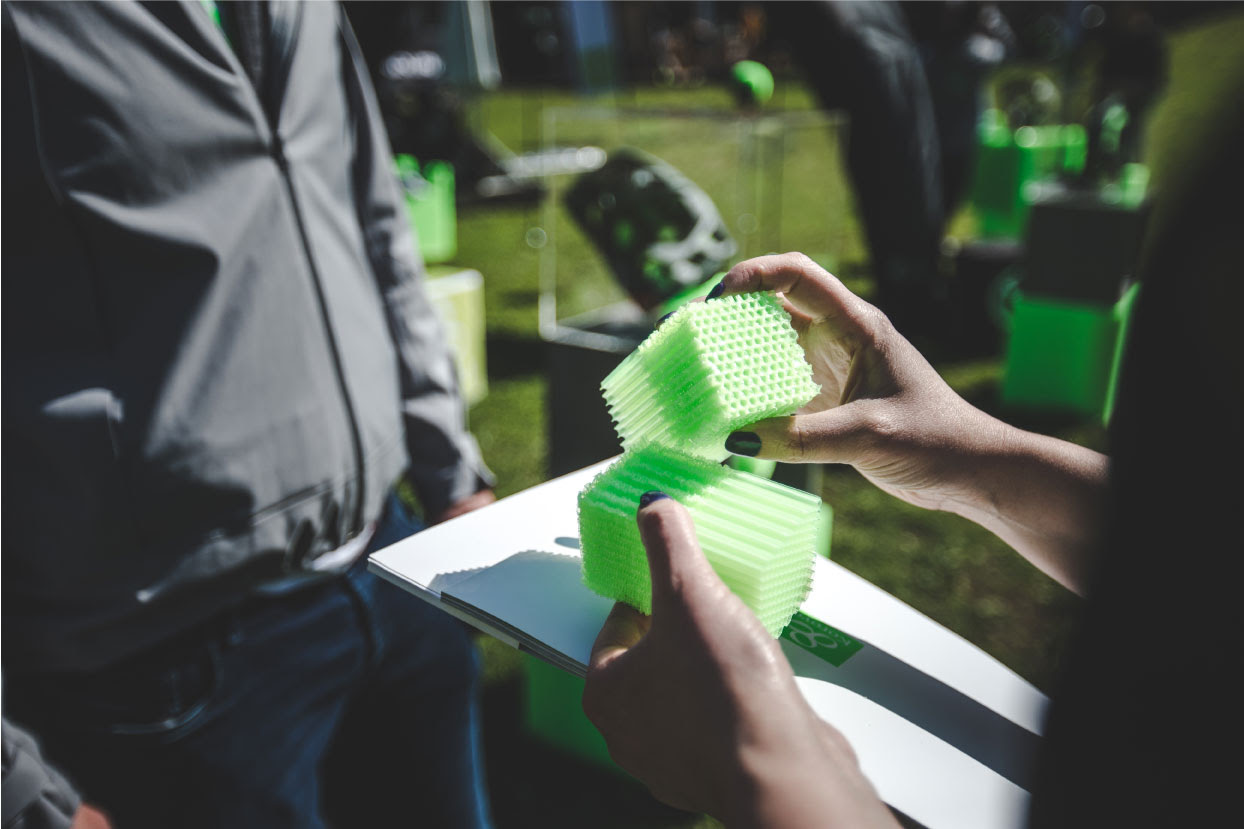

The Koroyd technology was developed from an airspace project after an aviation disaster that was widely covered by the media in the United Kingdom. The resulting material is a set of extruded and thermally welded tubes that crumple instantly and evenly during an impact, absorbing more force more reliably than any other technology.

Koroyd is a thermally welded tubular structure used in various products, from sports helmets to skis, and from industrial worker protection to car seats for children. Koroyd's main goal is to absorb energy in case of impact and protect the user against serious injuries. Besides being an industry leading energy absorber, Koroyd is also highly breathable and ultralight. Modern and improved paragliding harness protector.

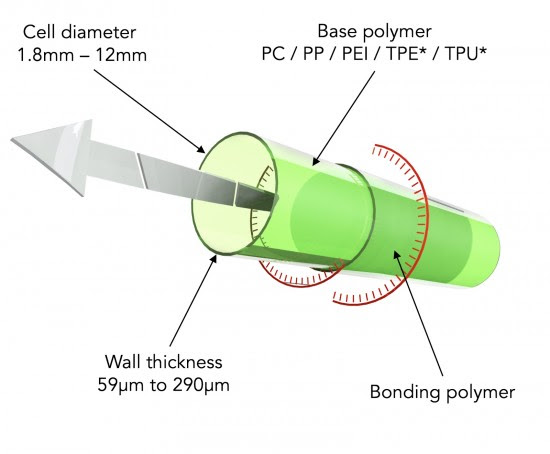

Koroyd's well-arranged structure and the tube's thin walls (59μm à 290μm) use a combination of controlled buckling and efficient deformation until their compression for high volumetric energy absorption.

Koroyd's properties are very similar to those of an energy absorber that's ideal in compression. The mechanical properties of Koroyd are related to their deforming behavior. Unlike traditional foam (e.g. EPS), Koroyd does not harden during the compression, the stress plateau is completely flat until the densification of the material at around 70 to 80% of compression.

This deformation is closer to the theoretical model of a mechanical energy absorber.

The graphic above shows the behaviour of Koroyd (HP60048) that we use during an almost static test compared to expanded polystrene (EPS50). This deformation test that allows characterizing a material is obtained by pressing it between two perfectly parallel plates.

IMPACT ENERGY ABSORPTION

Once the initial compression of an energy-absorbing material has been released (after an impact), it regains some energy due to its elastic behavior (rebound).

MINIMUM REBOUND

Since Koroyd has less elasticity compared to traditional foam, there is less risk of a second pulse from the energy absorbed during the loading phase (less rebound). Making it ideal options for back protector for paragliding harness.

PLASTIC DEFORMATION

With Koroyd, energy from an impact is converted to plastic deformation, a bit of heat and a bit of noise.

Would you like to learn more? Our next newsletter will be dedicated to the technical data and the results of our dynamic and static tests that made us choose this protection technology for our harnesses.